Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

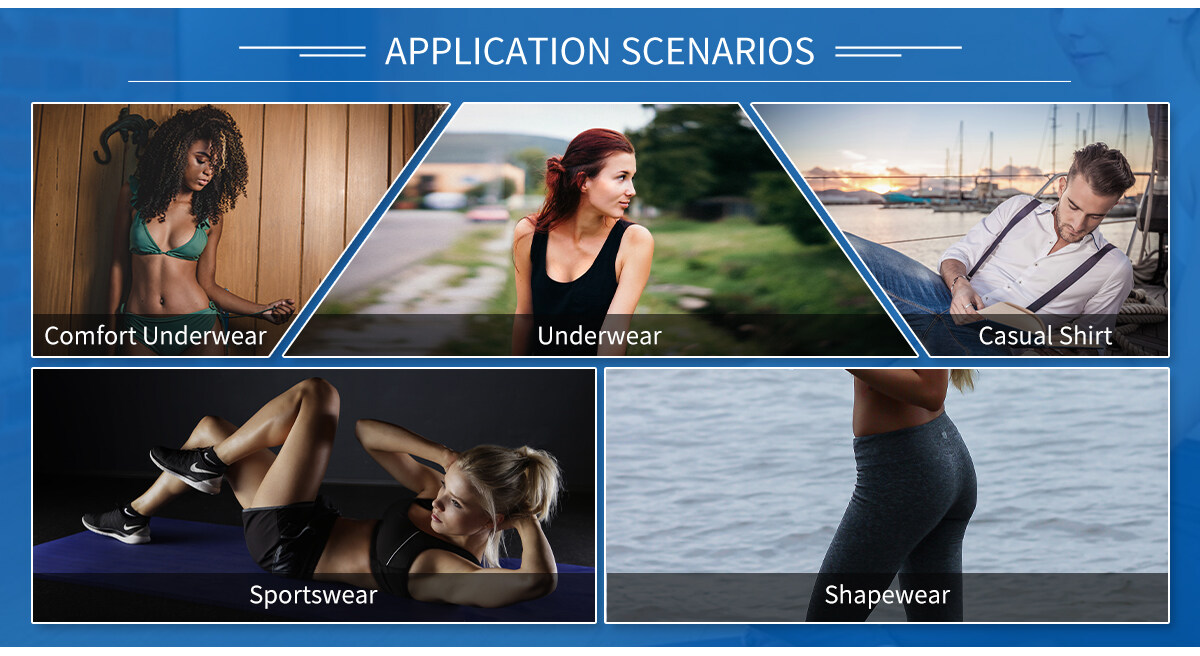

Black version pur glue is designed to be used on specific fabric

H-Series pur glue provides much high bonding adhesion than normal hot melt film, can reduce labor cost with automatic dispenser, improving quality and efficiency in bulk production at the same time.

H3(Black Version) is designed to be used on specific fabric.

Properites

| Article | Surface drying time | Hand feel | Operation Condition | RecommendedBonding Conditions | Curing Time(Hours) | Intervals between dotting & heat press(mins) |

|---|---|---|---|---|---|---|

| H3(Black version) | Fast(20-30s) | Very Soft | Softening Point: 110 - 130℃Spraying Temperature: 200 - 230℃ | Machine Setting: 55 - 95 °CDwell Time: 8 - 12 secondsPressure: 1 – 1.2 Bar | ≥24h | ≤ 20 mins |

Reactive polyurethane hot melt adhesive (PUR adhesive) does not contain water and solvents and has a solid content of 100%. It is a high-performance and environmentally friendly adhesive. Compared with ordinary hot melt adhesives, PUR adhesives have excellent comprehensive properties. It combines the characteristics of common solvent-free hot melt adhesives, high viscosity start, and fast assembly, but also has the water resistance, heat resistance, cold resistance, creep resistance, and dielectric properties of a unique reactive liquid adhesive performance. Its sizing temperature (120 °C) is lower than normal hot melt adhesives (150-180 °C) and can be used for some plastic parts.

The main feature of reactive polyurethane hot melt adhesives is that they can be cured under ambient conditions, which is lower than the application temperature of traditional hot melt adhesives. In short, this is a hot melt adhesive with better comprehensive performance and has been applied in the following industries:

1. Automobile structure and parts, such as windshield sealing and lamp assembly:

2. Textile industry and footwear industry, such as fabric seam bonding and shoe sole bonding, have the advantages of water resistance, softness, and comfort:

3. Book wireless binding, due to the flexibility of the adhesive layer, can make the book have a high degree of flatness when it is turned over, and prevent the formation of grooves at the binding place or the sudden closing of the book when reading, which is more superior than EVA binding;

4. The food packaging industry can withstand the high and low-temperature disinfection treatment stipulated in food hygiene

5. For the wood processing and furniture industry, the adhesive layer has good water resistance and aging resistance, and does not pollute and corrode wood:

6. In the electronics and electrical appliances industry, the adhesive layer is quickly cured, with no need to mix glue and the curing shrinkage rate is small, especially suitable for the bonding of precision components in the electronic and electrical industries.